Keeping grease traps clean with natural grease trap blocks and liquid FOG eating bacteria

So...what is the definition of a Grease Trap? Do you wonder what exactly a grease trap is? Probably not, you probably already know and are looking for an inexpensive and cheap way to keep things moving without regular clean-outs.

Yep...chances are if you are reading this you already know what a messy and stinky and horrible place a restaurant trap can be and you are looking for a way to clean the darned thing and reduce the amount of time and money it takes to shower off the congealed fats and oils that can clog the drains. Increasingly, municipalities are becoming more and more strict with regards to what is discharged into the main sewer system.

Our Favorite Products

Now on Amazon

As an Amazon affiliate we may recieve payment for purchases made through Amazon.

Commercial Drain Maintainer

Liquid Enzyme Clog Remover, Cleans and Deodorizes, Reduces Drain Blockages

1 Gal

|

Restaurants deal with large amounts of FOG (fats, oils and grease) on a daily basis and typically these elements collect in the grease trap.

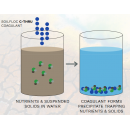

A grease trap is sometimes also called a grease interceptor. Basically this is a small mechanical receptacle that is spliced in between a restaurants drain line and the main sanitary sewer line. This grease interceptor, or trap, allows for the separation and collection of fats, oils and greases (FOG) from the used water, preventing these materials from entering the main municipal sewer system.

The grease trap usually located inside of the kitchen or somewhere in the restaurant plumbing system or sometimes the receptacle is on the outside of the building.

Many large restaurants, hospitals, campsites, parks and recreational parks or school kitchens will have their grease traps and grease interceptor located outside of the principal facility, usually in the ground in a secure storage system.

Smaller restaurants and fast food chains usually have smaller trap systems indoors sometimes right in the kitchen for easy access and cleaning.

Cleaning these traps is a dirty job. Manually swabbing out the fats and oils from these receptacles is a tough job. The spackle and buildup of hardened and congealed fats and oils is tough to scour clean. This buildup reduces the efficiency of the entire system and one of the worst symptoms of a dirty or clogged grease trap is that the effluent that drains into the municipal sewer system is often over the threshold for discharge levels which can lead to fines or citations.

Understanding the basic function of a grease trap system

Commercial kitchens use fats, oils and grease as part of the process of preparing food. The disposal of these elements can create issues as these coagulated substances can clog and block municipal sewer line systems.

More and more by-laws and environmental protection laws are cracking down on these commercial kitchens that do not meet specific targets and overload the sewer system with excessive amounts of grease, oils and fat.

A grease trap is basically a mechanical system where the grease, oil and fats are allowed to separate from the effluent of the kitchen establishment so that the coagulated fats can cordoned off and collected before they can be flushed into the sewer system.

The properly functioning and well maintained grease trap slows down the flow of water from drains (floor drains, dishwasher drains, cooking surface drains) and allowing the fats, grease and oils time to cool so that the fat content can rise to the surface and heavier solids to fall to the bottom of the trap allowing only the cleanest waters to pass into the main sewer line of the municipality.

Using the natural grease eating bacteria to reduce this coagulated mess will reduce the pumping time and pumping expense that is required. Without the proper monitoring of the levels of FOG's in a system issues like foul odors, drain blockages and sewer backups can result. Adding bacteria is the easiest way to ensure compliance with local laws and to reduce cleaning and pumping costs and time-loss.

A regular application of either a liquid, powdered or block format is now the new standard operating practice for any smart restaurant or commercial kitchen. They are an ultra-easy and super-convenient way to ensure lift stations or any sort of industrial trap system are clean and grease-free.

Our Selection of Grease Trap Products are now on Amazon

As an Amazon affiliate we may recieve payment for purchases made through Amazon.

Grease Trap Blocks

Blocks come ready to use. Each block comes inside a mesh straining bag with ropes to suspend the block properly in any sized grease trap. Simply suspend each block from the included rope and tie it off so that the block remains completely submerged in the grease trap's water at all times. Avoid letting the block sink to the very bottom of the grease trap, where it can become caked with grease and unable to dissolve properly.

Safe without harsh chemicals or enzymes:

These grease trap slow-release blocks do not contain any surfactants or enzymes which, more and more, have become increasingly banned by municipalities and local governments due to their negative effect of waste water sewage treatment treatment downstream.

These grease trap blocks are made of a high concentration of beneficial grease digesting bacteria that quickly and effectively eat and degrades FOG, converting it into basic carbon dioxide and water thus eliminating the risk of accumulation and coagulation further downstream in the plumbing or beyond the municipal sewer system.

These time-release slow-dissolve blocks are the simplest, most effective way to control and break down the accumulation of fats, oils and grease (FOG) in a grease trap. These handy blocks slowly dissolve and release a natural grease digesting bacteria that significantly reduces pump outs, cleaning and controls odors. The standard one pound blocks are ideal for smaller systems. In large systems it may be more efficient to use the two pound blocks every 4 weeks. Adjust according to the FOG output of your system.

Application Rates: Add one block per 250 gallon trap capacity per month. Adjust according to the FOG output of your system.

Grease & Waste Digester

Works naturally to help break down waste, grease, fats, oils, sugars and other organic matter This helps improve grease trap performance. Works naturally to help break down waste, grease, fats, oils, sugars and other organic matter This helps improve grease trap performance.

It is also safely cleans clogged and problem drains, including floor drains, beverage tower drains, urinals and commodes

Enzyme Magic Grease & Waste Digester will not generate heat or corrode plumbing.

It deodorizes by using enzymes to attack the organic source of odors Our grease and Waste Digester is pH neutral, Safe for storage, and Non-Corrosive Contains

No phosphates, it is biodegradable and Eco-Friendly

Comes in convenient 4 oz. pouches to prevent waste

Reduce labor time for dosage maintenance and the need for pump-outs by automating septic and grease trap maintenance with Bio-Flow Block.

Directions: Complete directions on product label Easy to use, simply suspend the block into the treatment area, allowing the block to be placed just away from the higher flow areas. The block will dissolve over a 45-90 day period as the waste water flows over it. Higher flows will result in faster degradation of the block.

Grease Trap Concentrated Liquid Cleaner

This is a liquid bacteria formulation for the treatment and maintenance of grease traps. The bacteria in NE1000 break down and digest fats, oils and greases (FOG) along with other organic waste that accumulate in grease traps and drain lines.. This powerful and natural grease digesting bacteria significantly reduces pump outs, cleaning and controls odors. This is a liquid bacteria formulation for the treatment and maintenance of grease traps. The bacteria in NE1000 break down and digest fats, oils and greases (FOG) along with other organic waste that accumulate in grease traps and drain lines.. This powerful and natural grease digesting bacteria significantly reduces pump outs, cleaning and controls odors.

Application Rates: Set the automated dosing injector to apply 4 fluid ounces per 100 gallons of grease trap capacity every 24 hours. Adjust according to the FOG output of your system. Can also be poured directly into drain lines.

Each gallon of grease trap liquid concentrate will treat: - 100 gallon capacity grease trap for about 32 days. - 250 gallon capacity grease trap for about 13 days.

Dry Grease Trap Packets

Pre-dosed 2 ounce dry powder packets. Simply toss one packet of powder per 100 gallons of grease trap capacity every 1 to 4 weeks as required.

This is a dry powdered grease trap bacteria formulation for the treatment and maintenance of grease traps. The bacteria in this formula break down and digest fats, oils and greases (FOG) along with other organic waste that accumulate in grease traps and drain lines. This powerful and natural grease digesting bacteria significantly reduces pump outs, cleaning and controls odors.

Application Rates: Add one 2 ounce soluble packet per 100 gallons of grease trap capacity every week or as required. Adjust according to the FOG output of your system. Can also be mixed with water and poured directly into drain lines.

|

Maintenance and cleaning of grease trap interceptors

Cleaning a grease trap is a horrible job. Asking your employees to clean the grease trap will not make them happy to comply. The easiest way to maintain the system and reduce costs and avoid any fines for noncompliance is to use a natural bacterial additive (slow dissolve block, liquid, or powder) to the drain lines or interceptor tank.

Dry Grease Crystals

Established commercial fast-food or industrial kitchen facilities typically use one of the more well-known brands of grease traps. When initially asking where to buy a grease trap you should look at some of the regulatory requirements of your state or province and then calculate the proper size of the system you will need. Some of the more popular brands of grease traps available for retail and commercial sale in North America are manufactured by Dormont grease traps, Big Dipper grease traps, Zurn grease traps, Jonesspec grease traps. Whenever purchasing an important system for a commercial or municipal enterprise it is recommended to always look for a local supplier and installer of such a system. Once you have your system installed correctly the use of bacteria is the key to proper care in the future. Established commercial fast-food or industrial kitchen facilities typically use one of the more well-known brands of grease traps. When initially asking where to buy a grease trap you should look at some of the regulatory requirements of your state or province and then calculate the proper size of the system you will need. Some of the more popular brands of grease traps available for retail and commercial sale in North America are manufactured by Dormont grease traps, Big Dipper grease traps, Zurn grease traps, Jonesspec grease traps. Whenever purchasing an important system for a commercial or municipal enterprise it is recommended to always look for a local supplier and installer of such a system. Once you have your system installed correctly the use of bacteria is the key to proper care in the future.

The bacteria to clean the interceptor comes in powder, block or liquid formats. The powders and blocks are often preferred as they are lighter and cheaper to ship. Liquids are easily poured into drains. The best procedure is the one that works best for your staff. A block put into the trap once a month or every two weeks is often the easiest. The powders can be tossed into the open trap easily and the liquids can be mixed and poured into the drain line at the end of the night after the kitchen staff or bar has closed.

Beyond the actual grease interceptors, adding any of these products to all drains will reduce the slow accumulation of pipe clogging substances, those damaging and odor causing oils and fats and grease. By making daily or weekly dosing of the drain system with sludge devouring microbes will ensure that there is no clogging of any plumbing lines or drains and no buildup of odors due to crusts of organic materials forming on pipes and drain sleeves.

Instead of contracting out costly servicing by septic pumping and cleaning services to haul and pump accumulated solids and grease it makes fiscal sense to use natural bacteria and do the job in-house to reduce labor costs and expenses. Even by reducing the frequency of pump-outs you can save money and time. Avoiding any citations and fines is also in the best interest of any business or corporate structure.

Clogged drains and backed-up sewers can lead to shutdowns and inventory loss. Something as seemingly benign and unseen as a grease trap can be a financial hardship if not properly cleaned and cared for. The simple, regular addition of liquid or dry cultures into the system will reduce losses to almost zero and ensure smooth running pipes and grease traps.

Benefits of using grease trap bacteria agents

• Helps eliminates the frequency or the need for grease trap pumping

• Greatly improves and restores drain lines

• Eliminates the need for frequent drain jetting and pressure washing

• Eliminates the odors and smells from grease traps

• Cost-effective control and adherence to pollutant discharge requirements

• Environmentally safe

• Easily and automatically digests & liquefies solids

• Eliminates costly plumbing service and emergency drain cleaning due to blockage

• Extends the life of drains, fixtures and mechanics of the grease trap system

• Helps maintains the proper pH in grease traps

• Helps control TSS (Total Suspended Solids)

• Constant assurance that F.O.G. levels are in compliance with municipal discharge requirements

• Restores lines and pipes and drains to their original diameter

Some interesting links on grease traps:

1.Wikipedia:

"Grease traps (also known as grease interceptors, grease recovery devices and grease converters) are plumbing devices designed to intercept most greases and solids before they enter a wastewater disposal system. Common wastewater contains small amounts of oils which enter into septic tanks and treatment facilities to form a floating scum layer. This scum layer is very slowly digested and broken down by microorganisms in the anaerobic digestion process. However, very large amounts of oil from food production in kitchens and restaurants can overwhelm the septic tank or treatment facility, causing a release of untreated sewage into the environment. Also, high viscosity fats and cooking greases such as lard solidify when cooled, and can combine with other disposed solids to form blockages in drain pipes. Grease traps have been used since the Victorian days, although Nathaniel Whiting obtained the first patent for a modern day grease trap in the late 1800s. They are used to reduce the amount of fats, oils and greases (FOGs) that enter the main sewers. Effectively they are boxes within the drain run that flows between the sinks in a kitchen to the sewer system. They only have kitchen waste water flowing through them and are not served by any other drainage system such as toilets. They can be made from a number of different materials; e.g. stainless steel, plastics, concrete & cast iron. They range from 35 lifter capacity to 45,000 lifters and above capacity. They can be located above ground, below ground, inside the kitchen or outside the building.

Restaurant and foodservice kitchens produce a lot of waste grease which is present in the drain lines from the various sinks dishwashers and cooking equipment such as combi ovens and commercial woks. If not removed the grease will congeal within the sewer and cause blockages and back-ups. In the United States, sewers back up annually “an estimated 400,000 times, and municipal sewer overflows on 40,000 occasions”.[1] The EPA has determined that sewer pipe blockages are the leading cause of sewer overflows, and grease is the primary cause of sewer blockages.[2] Even if accumulated FOG does not escalate into blockages and sanitary sewer overflows, it can disrupt wastewater utility operations and increase operations and maintenance requirements” [3] For these reasons, depending on the country, nearly all municipalities require commercial kitchen operations to fit some kind of interceptor device to collect the grease before it enters the sewer. Additionally where FOG is a concern in the local wastewater collection system communities have set up inspection programs to ensure that these grease traps and/or interceptors are being maintained on a routine basis. ."

Wikipedia: https://en.wikipedia.org/wiki/Grease_trap

2. Goslyn™ Informs On Passive Grease Trap Technology

"Passive Grease Traps and Grease Interceptors are metal or plastic tanks required in foodservice facilities to prevent fats, oil, and grease from entering the sanitary sewer or septic system. Grease interceptors are large in-ground outdoor tanks that (usually cement or fibreglass) trap grease and food solids from foodservice kitchen facilities. Conventional Grease Traps are referred to as passive grease traps and gravity based grease traps. Grease Traps were originally designed over 100 years ago. Passive Grease Trap technology has remained virtually unchanged since the 1880's. Over fifty percent of all sanitary sewer overflows in Canada and the USA result from grease blockages. What is the cost of a raw sewage spill? "

Goslyn™ Informs On Passive Grease Trap Technology https://www.greasetrap.ca/grease-trap-gallery.htm

3.Boston Water and Sewer Commission

"Can I Add Any Cleaning Agents to the Trap to Help Clear the Grease Faster? No. Never add bleach, emulsifers, enzymes or any other chemical to the grease trap. Tese agents harm the natural bacteria that eat grease and oils in grease traps. Te only additive allowed into the sewer system by BWSC is bacteria. Bacteria consume fat, oil and grease in the trap, turning them into water and carbon dioxide. What Methods of Disposal are Available for Used Grease? Te food establishment's waste hauler or renderer that removes used fryolater grease and oil normally accepts materials removed from the grease trap. Large in-ground grease traps normally hold 500 gallons or more and are usually cleaned by a contractor equipped to deal with the large quantities of grease, oil and non-foatables. It is the responsibility of the establishment owner to ensure the trap is completely cleaned. ."

Boston Water and Sewer Commission https://www.bwsc.org/REGULATIONS/GREASE_TRAP_GUIDELINES.PDF

4. Bio-Systems International

"BIOBUG® DC is specially formulated and packaged for direct addition to drains and grease traps in restaurants and commercial buildings. The concentrated bacterial formulation is also ideal in residential applications for cleaning and maintaining drains and garbage disposals, while removie grease trap odor. To assure optimal performance of these organisms, under the toughest conditions, they are produced and blended together with “high potency” nutrients, stimulants and surfactants. BIOBUG® DC contains microorganisms that are capable of degrading a wide range of animal and vegetable oils and greases as well as food residuals combined with natural biological enhancers, micronutrients and macronutrients. ."

Bio-Systems International https://www.biobugs.com/Products/HII/GreaseTrapDrainPowder/tabid/434/Default.aspx

5. REX-BAC-T® The Environmentally Safe, 100% Natural, Alternative To Current Waste Treatment Methods

"Bioaugmentation is the introduction of highly efficient natural microbial strains grown in environmentally controlled fermentation processes that are inoculated into the waste grease interceptor system to treat contaminated wastewater. These highly effective microbes use the simple and complex carbohydrates as a food source yielding water and carbon dioxide. In grease interceptors, bioaugmentation is used to ensure that the in situ microorganisms that are selectively chosen to efficiently degrade or digest the (FOG) contaminating the wastewater maintain the dominant population culture and most efficient microbes.."

REX-BAC-T® The Environmentally Safe, 100% Natural, Alternative To Current Waste Treatment Methods https://www.rex-bac-t.com/c-51-grease-trap-treatments.aspx

|

Established commercial fast-food or industrial kitchen facilities typically use one of the more well-known brands of grease traps. When initially asking where to buy a grease trap you should look at some of the regulatory requirements of your state or province and then calculate the proper size of the system you will need. Some of the more popular brands of grease traps available for retail and commercial sale in North America are manufactured by Dormont grease traps, Big Dipper grease traps, Zurn grease traps, Jonesspec grease traps. Whenever purchasing an important system for a commercial or municipal enterprise it is recommended to always look for a local supplier and installer of such a system. Once you have your system installed correctly the use of bacteria is the key to proper care in the future.

Established commercial fast-food or industrial kitchen facilities typically use one of the more well-known brands of grease traps. When initially asking where to buy a grease trap you should look at some of the regulatory requirements of your state or province and then calculate the proper size of the system you will need. Some of the more popular brands of grease traps available for retail and commercial sale in North America are manufactured by Dormont grease traps, Big Dipper grease traps, Zurn grease traps, Jonesspec grease traps. Whenever purchasing an important system for a commercial or municipal enterprise it is recommended to always look for a local supplier and installer of such a system. Once you have your system installed correctly the use of bacteria is the key to proper care in the future.